Aluminiumoxid-Keramikrohre – Vorteile als iterative Produkte

Einführung

Aluminiumoxid-Keramikrohre, auch Aluminiumoxid-Keramikrohre genannt, sind weithin für ihre außergewöhnlichen Eigenschaften und vielseitigen Einsatzmöglichkeiten in verschiedenen Branchen bekannt. In diesem Artikel untersuchen wir die Vorteile von Aluminiumoxid-Keramikrohren als iterative Produkte und konzentrieren uns dabei auf ihre spezifischen Anwendungen und darauf, wie sie Rohre aus herkömmlichen Materialien übertreffen. Wir werden auch die Nachteile herkömmlicher Materialrohre im Vergleich besprechen.

Anwendungen von Aluminiumoxid-Keramikrohren

Isolierung in Öfen und Brennöfen

Aluminum oxide ceramic tubes excel as insulation components in high-temperature environments, such as furnaces and kilns. Their excellent thermal insulation properties allow for precise temperature control, minimizing heat loss and improving energy efficiency in industrial processes.

Electrical Insulators and Sleeves

With superior electrical insulation capabilities, alumina ceramic tubes are widely used as insulators and sleeves in electrical systems. They provide reliable insulation and protection against electrical currents, ensuring safe operation in various applications, including power distribution, electronics, and high-voltage equipment.

Corrosive Chemical Processing

Aluminum oxide ceramic tubes exhibit exceptional chemical resistance, making them ideal for corrosive chemical processing. They can withstand exposure to aggressive acids, alkalis, and other corrosive substances without deteriorating or compromising performance. These tubes find applications in chemical plants, laboratories, and the pharmaceutical industry.

Catalyst Support

Alumina ceramic tubes are commonly utilized as catalyst supports in various reactions. Their high surface area and stability enable efficient catalyst loading and distribution, promoting catalytic activity and enhancing reaction rates. This makes them valuable in chemical and petrochemical industries for processes such as refining, hydrogenation, and synthesis.

High-Purity Environments

In industries that require high-purity environments, such as semiconductor manufacturing and pharmaceuticals, alumina ceramic tubes are favored due to their inherent purity and low contamination potential. They do not release particles or impurities that could jeopardize product quality, making them suitable for critical applications where cleanliness is paramount.

Thermal Management in Electronic Devices

Aluminum oxide ceramic tubes play a crucial role in thermal management for electronic devices. They are used as heat spreaders and heat sinks, efficiently dissipating heat generated by electronic components. Their high thermal conductivity allows for effective heat transfer, enhancing the performance and reliability of electronic devices, including LEDs, power modules, and computer processors.

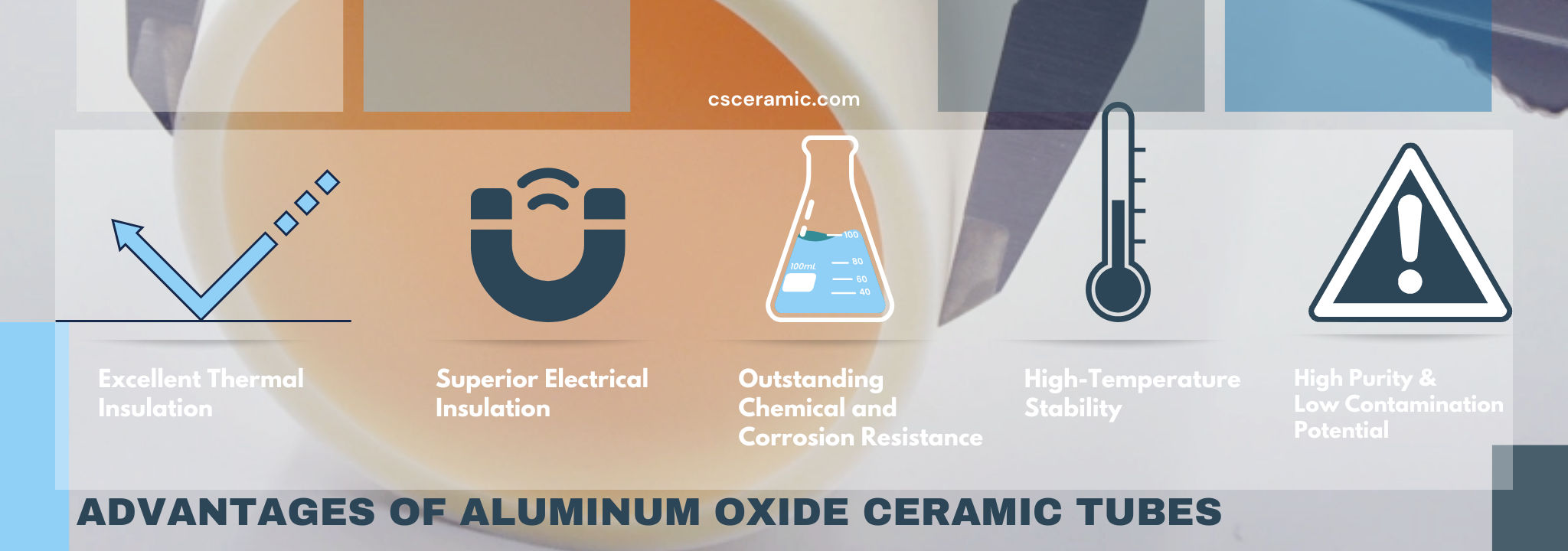

Advantages of Aluminum Oxide Ceramic Tubes

Excellent Thermal Insulation

Alumina ceramic tubes possess outstanding thermal insulation properties, allowing them to resist high temperatures and maintain thermal stability. They effectively minimize heat transfer, preventing energy loss and promoting efficient heat retention. This characteristic makes them indispensable in applications where temperature control is crucial.

Superior Electrical Insulation

Aluminum oxide ceramic tubes demonstrate excellent electrical insulation capabilities, with high dielectric strength and low electrical conductivity. They can effectively isolate electrical components and prevent electrical leakage or short circuits. Their electrical insulation properties contribute to enhanced safety and reliable performance in electrical systems.

Outstanding Chemical and Corrosion Resistance

Alumina ceramic tubes exhibit exceptional resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. They remain unaffected by corrosive substances, ensuring long-term durability and reliable operation even in harsh chemical environments. This chemical resistance reduces maintenance requirements and extends the lifespan of equipment.

High-Temperature Stability

One of the most significant advantages of aluminum oxide ceramic tubes is their remarkable stability at high temperatures. They can withstand extreme heat without warping, softening, or undergoing structural changes. This high-temperature stability makes them suitable for applications where exposure to intense heat is common, such as furnaces, kilns, and high-temperature processing.

High Purity and Low Contamination Potential

Alumina ceramic tubes are known for their high purity and low contamination potential. They are chemically inert and do not release particles or impurities into the surrounding environment. This purity is crucial in industries that require strict cleanliness standards, ensuring the integrity of sensitive processes and products.

Comparison with Traditional Material Tubes

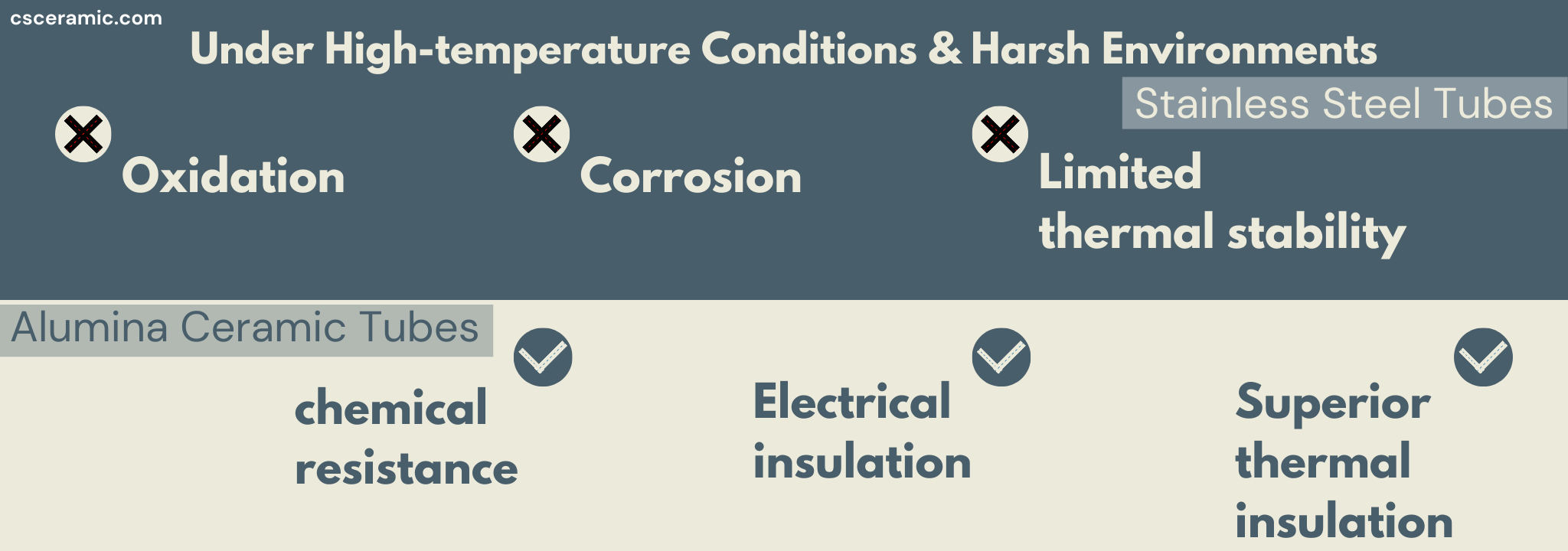

Stainless Steel Tubes V.S Alumina Ceramic Tubes

In comparison to stainless steel tubes, alumina ceramic tubes offer superior thermal insulation, electrical insulation, and chemical resistance. Stainless steel tubes may suffer from oxidation, corrosion, and limited thermal stability under high-temperature conditions. Alumina ceramic tubes outperform stainless steel tubes in harsh environments, providing extended durability and performance.

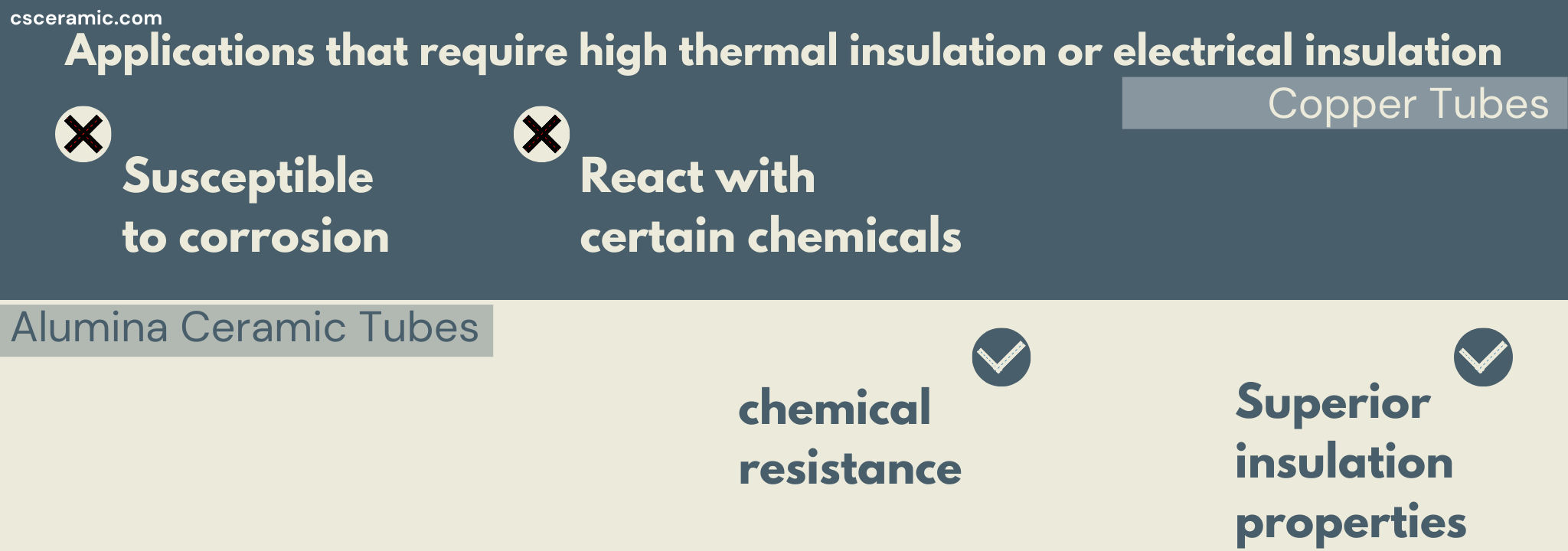

Copper Tubes V.S Alumina Ceramic Tubes

Copper tubes, although excellent conductors of heat and electricity, are not suitable forapplications that requirehigh thermal insulation or electrical insulation. Copper issusceptible to corrosion and mayreact with certain chemicals. In contrast, alumina ceramic tubes offersuperiorinsulation properties andchemical resistance, making them a more favorable choice in many scenarios.

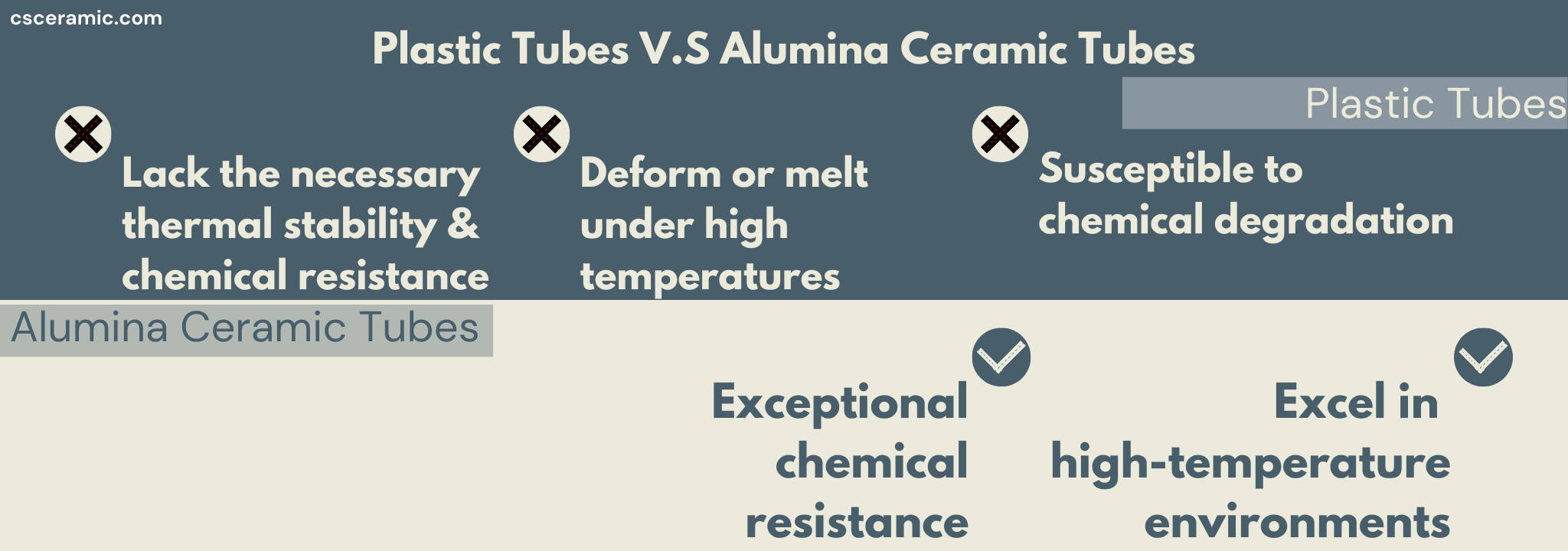

Plastic Tubes V.S Alumina Ceramic Tubes

Plastic tubes oftenlack the necessary thermal stability and chemical resistance required for demanding applications. They maydeform or melt under high temperatures and can besusceptible to chemical degradation. Alumina ceramic tubes, on the other hand,excel in high-temperature environments and exhibitexceptional chemical resistance, making them a reliable choice for critical operations.

Conclusion

Aluminum oxide ceramic tubes, or alumina ceramic tubes, provide significant advantages over traditional material tubes in various industrial applications. Their excellent thermal insulation, superior electrical insulation, outstanding chemical and corrosion resistance, high-temperature stability, and high purity make them invaluable in numerous industries. Whether in furnace insulation, electrical systems, corrosive chemical processing, catalyst support, high-purity environments, or thermal management in electronics, alumina ceramic tubes offer unparalleled performance and reliability.

Frequently Asked Questions (FAQs)

Q1: Can alumina ceramic tubes be used in cryogenic applications?

Ja, Aluminiumoxid-Keramikrohre halten auch kryogenen Temperaturen stand. Ihre thermische Stabilität erstreckt sich bis zu niedrigen Temperaturen, wodurch sie für Anwendungen in der Kryotechnik und Kältetechnik geeignet sind.

F2: Können Aluminiumoxid-Keramikrohre leicht in komplexe Formen gebracht werden?

Aluminiumoxid-Keramikrohre können mithilfe fortschrittlicher Keramikverarbeitungstechniken in verschiedenen Formen und Größen hergestellt werden. Ihre Vielseitigkeit ermöglicht die Erstellung komplexer Geometrien, um spezifische Anwendungsanforderungen zu erfüllen.

F3: Können Aluminiumoxid-Keramikrohre für bestimmte Anwendungen angepasst werden?

Ja, Aluminiumoxid-Keramikrohre können individuell angepasst werden, um den besonderen Anforderungen verschiedener Anwendungen gerecht zu werden. Dazu gehören Abweichungen bei Abmessungen, Toleranzen, Oberflächenbeschaffenheiten und zusätzlichen Merkmalen wie Flanschen oder Anschlüssen.

F4: Sind Aluminiumoxid-Keramikrohre im Vergleich zu Rohren aus herkömmlichen Materialien teuer?

Aluminiumoxid-Keramikrohre sind im Allgemeinen teurer als Rohre aus herkömmlichen Materialien. Ihre langfristige Haltbarkeit, reduzierte Wartungskosten und verbesserte Leistung rechtfertigen jedoch oft die Anfangsinvestition.

F5: Wie kann ich Aluminiumoxid-Keramikrohre für meine spezifischen Anwendungsanforderungen erhalten?

Um Aluminiumoxid-Keramikrohre für Ihre spezifischen Anwendungsanforderungen zu erhalten, wird empfohlen, sich an seriöse Hersteller oder Lieferanten zu wenden, die auf Keramikprodukte spezialisiert sind. Sie können Ihnen Beratung und Anpassungsmöglichkeiten bieten und hochwertige Aluminiumoxid-Keramikrohre liefern, die auf Ihre Anforderungen zugeschnitten sind.

Vielen Dank fürs Lesen. Wir laden Sie ein, CSCERAMIC für weitere Informationen zu besuchen , wenn Sie mehr über industrielle Keramikmaterialien und das fortschrittliche Sortiment an Keramikprodukten, die wir anbieten, erfahren möchten.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522