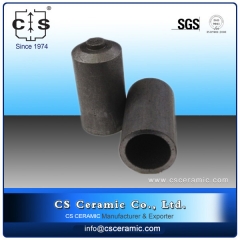

Keramiktiegel Leco 528-018. Hersteller von Kohlenstoff-Schwefel-Tiegeln und CS-Tiegeln für LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 AN. Wird für die Elementaranalyse des Kohlenstoff-Schwefel-Analysators verwendet.

Lesen Sie mehr...

Beidseitig offene Aluminiumoxidrohre werden häufig in verschiedenen Industrie- und Laboranwendungen eingesetzt . _ _ _ _ _ Sie sind ideal für den Einsatz in Prozessen wie Heizen , Kühlen und Trocknen und bieten eine hervorragende thermische und elektrische Isolierung . _ _

Lesen Sie mehr...

Aluminium - Keramiksubstratplatten sind die ideale Wahl für Anwendungen , die hohe Leistung , Zuverlässigkeit und Haltbarkeit erfordern . _ _ _ _ Es ist in verschiedenen Größen und Stärken erhältlich , um den unterschiedlichen Anwendungen gerecht zu werden .

Lesen Sie mehr...

Erreichen Sie mit unseren Bone Ash Cupels einen beispiellosen Reinheitsgrad. Diese Cupels wurden entwickelt, um Verunreinigungen und unerwünschte Elemente zu entfernen und ermöglichen es Ihnen, die wahre Essenz Ihrer Edelmetalle zu extrahieren.

Lesen Sie mehr...

Vorteile von Aluminiumoxidrohren: hohe Hitzebeständigkeit, gute Kältebeständigkeit, Hitzebeständigkeit, Beständigkeit gegen Säure- und Alkalikorrosion. Lange Lebensdauer. OEM wird akzeptiert.

Lesen Sie mehr...

Circle-Aluminiumoxid-Keramikstäbe haben ein höheres Verhältnis von Festigkeit zu Gewicht als andere Keramiken und können zur Herstellung leichterer und stärkerer Teile verwendet werden. Erhältlich in einer Vielzahl von Größen und Formen.

Lesen Sie mehr...

Ein Lumina-Tiegel und ein Boot werden häufig in der Labor- und Industrieanalyse sowie beim Schmelzen von Metall- und Nichtmetall-Materialproben eingesetzt. Erhältlich in verschiedenen Größen und Formen.

Lesen Sie mehr...

952018.906 100 μl Platin/Pt-Tiegel ( Probenschalen) für TA Instruments TA Q500/Q50/TGA 2950/2050 . Hersteller für TA-Tiegel und DSC-Probenschalen . Der TGA-Analysator von TA Instruments ist eine gute Alternative zu Probenbechern.

Lesen Sie mehr...

Zirkonoxidkeramik wird in Wellen, Kolben, Dichtungsstrukturen, der Automobilindustrie, Ölbohrgeräten, Isolierteilen in elektrischen Geräten, Keramikmessern, Ersatzteilen für keramische Haarschneidemaschinen mit hoher Dichte, Biegefestigkeit und Bruchfestigkeit verwendet. Wir können die Produkte gemäß den Zeichnungen, Mustern und Leistungsanforderun4

Lesen Sie mehr...

1. Stellen Sie Platin-/PT-Tiegel unterschiedlicher Größe herwie Sie brauchen.2. Senden Sie uns eine Konstruktionszeichnung oder Spezifikation von Platin/PT-Tiegeln. Hersteller von Platin-/PT-Tiegeln .CS CERMAIC CO.,LTD

Lesen Sie mehr...Keramiktiegel Leco 528-018. Hersteller von Kohlenstoff-Schwefel-Tiegeln und CS-Tiegeln für LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 AN. Wird für die Elementaranalyse des Kohlenstoff-Schwefel-Analysators verwendet.

Art.-Nr. :

CS001Suitable for : Leco Bruker Eltra Horiba Alpha

Material : ceramic

Part NO : 528-018 AR3818 90150 905.200.380.001

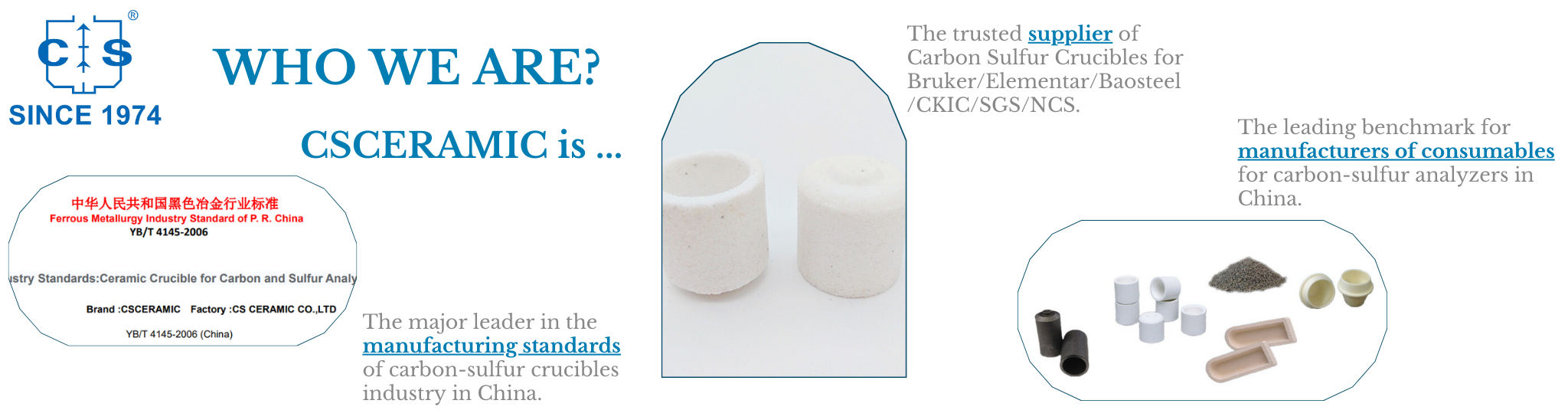

Wir sind...

Der vertrauenswürdige Lieferant von Kohlenstoff-Schwefel-Tiegeln für Bruker/Elementar/Baosteel/CKIC/SGS/NCS.

Und...

Der führende Anbieter von Herstellungsstandards für die Kohlenstoff-Schwefel-Tiegelindustrie in China.

Auch...

Der führende Maßstab für Hersteller von Verbrauchsmaterialien für Kohlenstoff-Schwefel-Analysatoren in China.

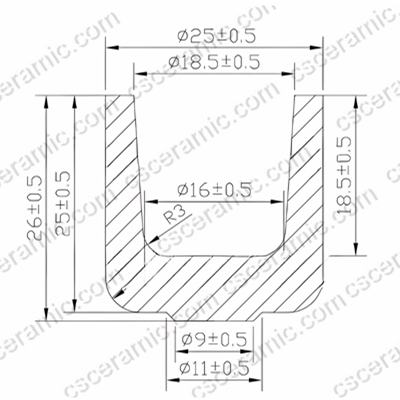

Abmessungen |

25mm*25mm |

Hauptmaterial |

Quarzglas |

Blindwert von Kohlenstoff und Schwefel |

C%<3ppm, S%<2ppm |

Max. Arbeitstemperatur |

1400°C |

Max. Temperatur schneller Veränderungen |

Bis zu 350°C |

Max. Physischer Druck |

45.000 psi |

Produktmenge |

1000PSC/CTN |

Produktmusterservice |

Kostenloses Angebot |

| Kompatible Instrumente |

|||

| Bruker G4 Icarus CS |

|||

| Eltra CHS580/CHS580A |

Eltra CS-2000 |

Eltra CS800 |

Eltra Helios |

| Horiba EMIA-320V2/920V2 |

Horiba EMIA820V/320V/220V |

||

| LECO® CS125/225 |

LECO® CS200/C200/S200/WC200 |

LECO® CS230 |

LECO® CS244/344/IR212/232 |

| LECO® CS400/C400/S400 |

LECO® CS444/IR412/432 |

LECO® CS600 |

LECO® CS600 |

| LECO® CS744 |

LECO® CS844 |

LECO® WR112 |

|

| Verbrauchsmaterialien Nr. |

|||

| Bruker® W- N009250423 /Q105054 |

|||

| Eltra® 90148/90149/90150/90152 _ |

|||

| LECO® 528-018 |

LECO® 002-308 |

LECO® 002-309 |

|

| Horiba® 905.200.380.001 |

Horiba® 905.200.380.001 AN |

Horiba® 1100132671 |

|

| Elementar® 905.200.380.001 AN |

|||

| SerCon® SC0893 |

|||

| Alpha® AR3818 |

|||

| a ) |

|

| Q: |

Was ist ein Kohlenstoff-Schwefel-Tiegel? |

| A: |

Ein Schwefelschmelztiegel aus Kohlepapier ist ein technisches Wasserfahrzeug, das bei der Kohlenstoff-/Schwefelanalyse eingesetzt wird. Es besteht aus einer Kohlenstoff-Schwefel-Legierung und ist für hohe Temperaturen ausgelegt. |

| B) |

|

| Q: |

Welche Auflösung hat ein Kohlenstoff-Schwefel-Tiegel? |

| A: |

Die Aufgabe eines Kohlenstoff-Schwefel-Tiegels besteht darin, die Menge an Kohlenstoff und Schwefel in einer Probe genau zu messen. Es wird in einer Vielzahl von Branchen eingesetzt, darunter Salben und Gas, Metallverarbeitung und chemische Verarbeitung. |

| C) |

|

| Q: |

Welches Schreibmaschinenmaterial ist alt, um einen Kohlenstoff-Schwefel-Tiegel herzustellen? |

| A: |

Kohlenstoff-Schwefel-Tiegel werden typischerweise aus einer Kohlenstoff-Schwefel-Legierung hergestellt. Diese Legierung ist so konzipiert, dass sie hohen Temperaturen standhält und genaue Ergebnisse liefert. |

| D) |

|

| Q: |

Wie oft sollte ein Kohlenstoff-Schwefel-Tiegel ausgetauscht werden? |

| A: |

Kohlenstoff-Schwefel-Tiegel sollten regelmäßig ausgetauscht werden, um präzise Ergebnisse zu gewährleisten. Es wird empfohlen, sie alle 100 Proben oder alle 6 Monate auszutauschen, je nachdem, was zuerst eintritt. |

| e) |

|

| Q: |

Welche Art der Lagerung ist für einen Kohlenstoff-Schwefel-Tiegel erforderlich? |

| A: |

Die Instandhaltung eines Kohlenstoff-Schwefel-Schmelztiegels sollte eine regelmäßige Reinigung und Inspektion umfassen. Der Schmelztiegel sollte außerdem von nassen und undefinierten Chemikalien ferngehalten werden. |

| F) |

|

| Q: |

Welche Sicherheitsvorkehrungen sollten bei der Verwendung eines Kohlenstoff-Schwefel-Tiegels getroffen werden? |

| A: |

Bei der Verwendung eines Kohlenstoff-Schwefel-Tiegels sollten Schutzmaßnahmen das Tragen einer Schutzbrille, Handschuhe und einer Gesichtsmaske umfassen. Außerdem ist darauf zu achten, dass der Tiegel nicht überfüllt wird und die Probe nicht zu stark erhitzt wird. |

| Referenzbild _ Du bist da |

Ich nenne den Namen |

Referenzbild _ ure |

Artikelname |

|

Wolframbeschleuniger |

|

Graphittiegel 776-247 |

|

Beschleuniger für Eisensplitter |

|

Graphittiegel 775-431 |

|

Wolfram/Zinn-Beschleuniger |

|

Graphittiegel 775-433 |

|

Keramiktiegelabdeckung |

|

C / S-Tiegel 23*23 24*24 26*26mm |

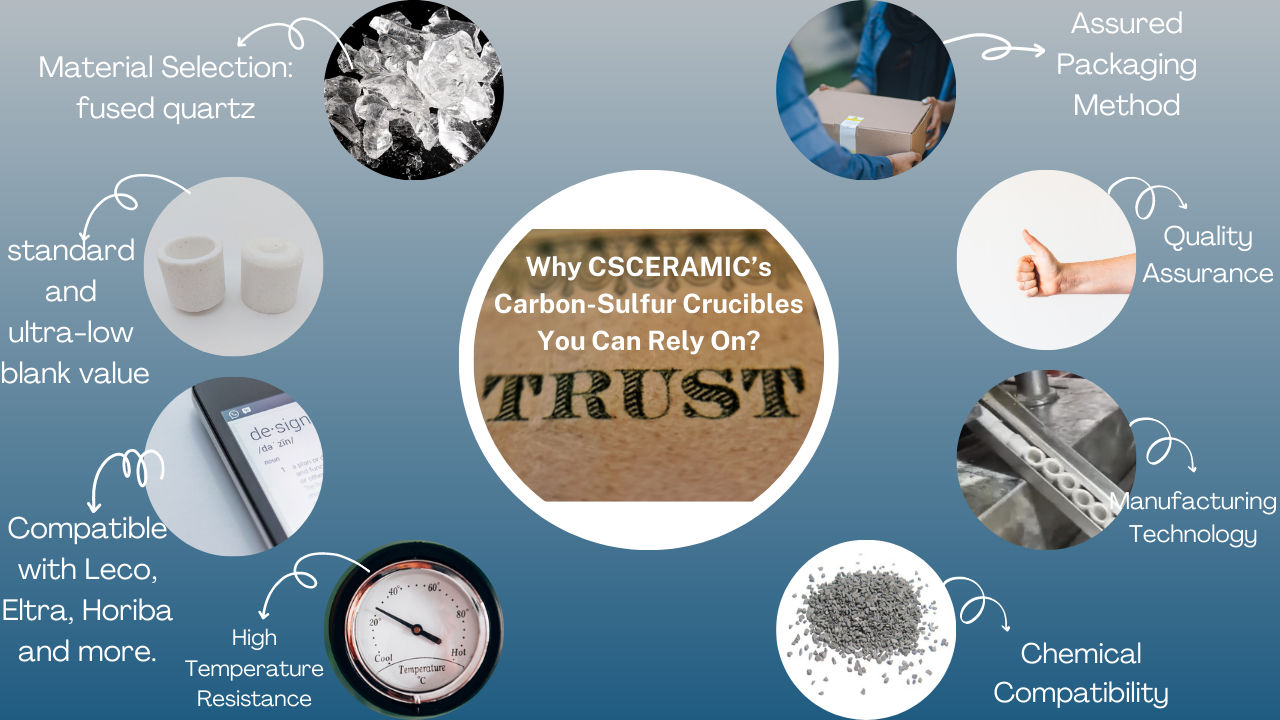

Unsere Tiegel bestehen aus chemisch inerten, hochwertigen Keramikmaterialien und bieten eine hervorragende thermische Stabilität und Korrosionsbeständigkeit. Als Hauptmaterial wird Quarzglas verwendet. Die ausgewählten Materialien halten hohen Temperaturen und korrosiven Umgebungen während Kohlenstoff-Schwefel-Analyseprozessen stand.

Unsere Kohlenstoff-Schwefel-Tiegel sind in zwei Ausführungen erhältlich: Standard-Blindwert (C% < 5 ppm, S% < 5 ppm) und extrem niedriger Blindwert (C% < 3 ppm, S% < 2 ppm). Die Tiegel sind frei von Verunreinigungen und gewährleisten so die Genauigkeit der Kohlenstoff-Schwefel-Messungen. Während des Herstellungsprozesses werden strenge Qualitätskontrollmaßnahmen umgesetzt, um die erforderlichen Reinheitsgrade zu erreichen.

Unsere Tiegel sind so konzipiert, dass sie perfekt zu Modellen von Kohlenstoff-Schwefel-Analysatoren von Marken wie Leco, Eltra, Horiba und anderen passen.

Die Kohlenstoff-Schwefel-Keramiktiegel verfügen über eine hohe Temperaturbeständigkeit und halten der während des Analyseprozesses erforderlichen Hochtemperaturerhitzung stand. Die Tiegel können ihre strukturelle Integrität und chemische Stabilität ohne Verformung oder Beschädigung bei Temperaturen von bis zu 1400 °C beibehalten.

Die Kohlenstoff-Schwefel-Keramiktiegel sind chemisch kompatibel mit den in der Kohlenstoff-Schwefel-Analyse verwendeten Substanzen und Reagenzien. Sie können Reaktionen oder Wechselwirkungen mit gängigen Säuren, Oxidationsmitteln und Reduktionsmitteln widerstehen, wodurch die Integrität der Proben gewahrt bleibt und genaue Ergebnisse gewährleistet werden. Unsere Tiegel haben Kompatibilitätstests erfolgreich bestanden und ihre Beständigkeit gegenüber chemischer Erosion nachgewiesen.

Bei der Herstellung von Keramiktiegeln geht es um die präzise Steuerung von Herstellungsparametern wie Temperatur, Druck und Trocknungsbedingungen durch Press- und Formprozesse. Dies gewährleistet eine gleichbleibende Qualität und Maßhaltigkeit.

Wir führen während des Herstellungsprozesses strenge Qualitätskontrollmaßnahmen durch, um die Zuverlässigkeit und Leistung unserer Tiegel sicherzustellen. Dazu gehören Inspektion und Prüfung von Rohstoffen, Prozessüberwachung, Dimensionsprüfungen und Leistungsbewertungen.

| Prüfung fertiger Keramiktiegel | |

| 1. | Überprüfen Sie den Tiegel auf Risse oder andere Schäden. |

| 2. | Stellen Sie sicher, dass der Tiegel ordnungsgemäß verputzt ist, um eine Kontamination zu verhindern. |

| 3. | Stellen Sie sicher, dass der Tiegel aus dem richtigen Material besteht und die für den Analysator nicht definierte Größe hat. |

| 4. | Stellen Sie sicher, dass der Schmelztiegel den für die Analyse erforderlichen Temperaturen standhält. |

Die Verpackungsmethode wurde wiederholten Tests unterzogen, um Brüche und Beschädigungen zu minimieren und sicherzustellen, dass die Tiegel im bestmöglichen Zustand an die Kunden geliefert werden.

1. Der Tiegel muss mit Alufolie oder weißem Papier aus reinem Aluminium verpackt sein und die Mindestverpackungseinheit beträgt 10 Stück pro Rolle. Die Rollen sollten in Papierkisten mit Kunststofffolie als Innenauskleidung gepackt und mit Wellpappe als Abstand zwischen den Schichten angeordnet werden. Die Gesamtmenge sollte für jeden Karton 1000 Stück betragen.

2. Wenn der Käufer besondere Anforderungen an die Verpackung hat, wenden Sie sich bitte an unseren Vertrieb.

Weitere zusätzliche Informationen, die Sie interessieren könnten...

1. Tragen Sie beim Umgang mit dem Tiegel Schutzhandschuhe und Schutzbrille.

2. Stellen Sie den Schmelztiegel in eine Schüssel mit warmem Wasser und geben Sie ein paar Tropfen Spülmittel hinzu.

3. Entfernen Sie mit einer einfachen Bürste einige Rückstände vom Tiegel.

4. Waschen Sie den Tiegel mit Streifenspülmittel und trocknen Sie ihn mit einem weichen Tuch ab .

Neben dem Rohmaterial und dem Herstellungsprozess kann die Tiegelbasislinie auch von der Absorption abhängen. Vor der Verwendung sollte der Einfluss von Wasser, SO2 und CO2 auf das Analyseergebnis vermieden werden. Zu diesem Zweck werden die beiden folgenden Methoden empfohlen.

Methode 1 : Legen Sie einen Kohlenstoff-Schwefel-Keramiktiegel in einen Hochtemperaturofen, erhöhen Sie die Temperatur auf 1200 °C und brennen Sie ihn 2 Stunden lang. Nehmen Sie ihn dann heraus, lassen Sie ihn abkühlen und legen Sie ihn nach Bedarf in einen Exsikkator (Aufbewahrungszeit nicht länger als 4 Stunden ) .

Methode 2 : Stellen Sie den Kohlenstoff-Schwefel-Analysetiegel in einen Röhrentiegelofen, induzieren Sie reinen Sauerstoff (Reinheit 99 % oder höher) und brennen Sie ihn mindestens 1 Stunde lang bei 1200 °C.

Hinweis: Produkte ohne Vorbehandlung können direkt verwendet werden, sofern ein normaler Kohlenstoff-Schwefel-Blindwert (10 ppm) akzeptabel ist.

A.1 Reagenzien

A.1.1 Flussmittel aus reinem Eisen: Die Partikelgröße beträgt weniger als 1,25 mm und der Massenanteil von Kohlenstoff und gebrochenem Eisen beträgt weniger als 0,0005 %.

A.1.2 Vanadiumpentoxid: Rein analysiert, vor der Verwendung 2 Stunden lang in einen Muffelofen bei 600 °C geben und als Reserve in einem Trockner abkühlen lassen.

A.1.3 Wolframfluss: Die Partikelgröße beträgt 0,4 bis 0,8 mm und der Massenanteil von Schwefel und Schwefel beträgt weniger als 0,001 % bzw. 0,0005 %.

A.1.4 Keramiktiegel: Verwenden Sie einen Keramiktiegel guter Qualität, brennen Sie ihn vor der Verwendung 4 Stunden lang bei 1200 °C in einem Muffelofen, kühlen Sie ihn dann über Nacht im Ofen ab und nehmen Sie ihn nach dem Abkühlen im Trockner auf Raumtemperatur heraus Reservieren.

A.1.5 Sauerstoff: hohe Reinheit (höher als 99,5 %)

A.2 Instrumente

A2.1 Hochfrequenz-Infrarot-Schwefelanalysator: Empfindlichkeit 0,00001 %

A.3 Analyseschritte

A.3.1 Probe: Mahlen Sie den „speziellen Tiegel für die Schwefelanalyse“ mit einem Achatmörser auf weniger als 0,15 mm und rösten Sie ihn 2 Stunden lang bei 105–110 °C. Nehmen Sie ihn dann heraus und kühlen Sie ihn als Reserve in einem Trockner auf Raumtemperatur ab.

A.3.2 Putztiegel (Sekundärtiegel): Geben Sie 1 Gramm Flussmittel aus reinem Eisen (A.1.1) und 1 Gramm Flussmittel aus Wolfram (A.1.3) in einen wie in Schritt A.1.4 behandelten Keramiktiegel. Stellen Sie den Tiegel in einen Hochfrequenz-Induktionsofen eines Infrarot-Kohlenstofftiegelanalysators, belüften Sie Sauerstoff und erhitzen Sie ihn mit dem Analyseprogramm. Nehmen Sie es nach Abschluss der Analyse ab, nachdem es leicht abgekühlt ist, und legen Sie es dann in einen Trockner (überprüfen Sie, ob keine Risse vorhanden sind), um es als Reserve auf Raumtemperatur abzukühlen.

A.3.3 Gerätekalibrierung

Wiegen Sie eine Standardprobe von 1,000 Gramm (C:0,00xx %, S:0,000xx % oder C:0,000xx %, S: 0,0000xx %) und geben Sie sie in den Schmelztiegel. Fügen Sie 1 Gramm reines Eisenflussmittel (A.1.1) und 0,6 Gramm Vanadiumpentoxid (A.1.2) hinzu und geben Sie den Massenwert der gewogenen Standardprobe in den Massenkompensator des Instruments ein. Starten Sie die Analyse, wiederholen Sie die Messung dreimal und nehmen Sie den Durchschnittswert für die Gerätekalibrierung.

A.3.4 Messung (Grundwert des Tiegelmaterials)

Wiegen Sie 1.000 Gramm Standardprobe genau ab, geben Sie sie auf den Boden des Schmelztiegels, geben Sie 1 Gramm reines Eisenflussmittel (A.1.1) und 0,6 Gramm Vanadiumpentoxid (A.1.2) hinzu und geben Sie den Massenwert der gewogenen Standardprobe in das Instrument ein Massenkompensator. Schließen Sie die Analyse ab. Der vom Instrument angezeigte Kohlenstoff- und Schwefelwert ist der Basiswert des Tiegelmaterials.

A.3.5 Messung (Grundwert des Tiegels)

Nehmen Sie einen vorbehandelten Keramiktiegel (oder einen Keramiktiegel ohne Vorbehandlung) und stellen Sie ihn auf eine elektronische Waage. Nachdem Sie das Nettogewicht ermittelt haben, fügen Sie 1 Gramm reines Eisenflussmittel (A.1.1) und 0,6 Gramm Vanadiumpentoxid (A.1.2) hinzu und geben Sie einen Massenwert von 1.000 Gramm in den Massenkompensator des Instruments ein. Schließen Sie die Analyse ab. Der vom Instrument angezeigte Kohlenstoff- und Schwefelwert ist der Basiswert des Tiegels.

Großer TGA-Keramiktiegel 529-047 621-331 20CC ALPHA AR9047 für LECO 701

Großer TGA-Keramiktiegel 529-047 621-331 20CC ALPHA AR9047 für LECO 701

20 ml großer Keramiktiegel 529-047 / 621-331 für LECO, Alpha AR9047. Hersteller von TGA-Keramiktiegeln für LECO TGA 500/501/601/701, MAC 400 / 500 . TGA-Aluminiumoxid-Tiegel /Pfannen für die TGA-Thermogravimetric Analyzer-Analyse TGA- Messung.

Tiegeldeckel aus Keramik 10mm 528-043/619-880 Eltra 88600-001 905.130.200.001

Tiegeldeckel aus Keramik 10mm 528-043/619-880 Eltra 88600-001 905.130.200.001

Tiegeldeckel mit 10mm Loch LECO 528-043 528-040 Horiba 905.130.200.001. Hersteller von CS-Tiegeldeckeln für LECO CS-400 CS-230 C4500 & C4501 Eltra CS800 für Kohlenstoff-Schwefel-Analysator.

Innerer Graphittiegel 775-431 775-892 Eltra 90180 für ONHp-Elementaranalysator

Innerer Graphittiegel 775-431 775-892 Eltra 90180 für ONHp-Elementaranalysator

LECO 775-431 Innerer Graphittiegel für Anwendungen, die einen einheitlichen Tiegel mit 775-433 Tiegeln erfordern. Eltra 90180 Horiba AR5431. Hersteller von inneren Graphittiegeln für LECO TC-400 TC-500 Ro-416, Eltra OH900 ON900.

Äußere Graphittiegel 775-433 Eltra 90185 Alpha AR433 für ONHp Elemental Analyzer

Äußere Graphittiegel 775-433 Eltra 90185 Alpha AR433 für ONHp Elemental Analyzer

LECO 775-433 äußerer Graphittiegel für Anwendungen, die einen einheitlichen Tiegel mit den Tiegeln 775-431 und 775-892 erfordern . Eltra 90185 Alpha AR433. Hersteller des inneren Graphittiegels für LECO TC-400 TC-500 Ro-416, Eltra OH900 ON900.

Keramische Verbrennungsschiffchen 529-204 529-204-250 für Kohlenstoff-/Schwefel-Analysator

Keramische Verbrennungsschiffchen 529-204 529-204-250 für Kohlenstoff-/Schwefel-Analysator

LECO wiederverwendbare keramische Verbrennungsboote 529-204 SerCon: SC0819, Hersteller von keramischen Verbrennungsbooten für LECO SC144. LECO-Verbrauchsmaterialien, Eltra Verbrauchsmaterialien.

Regulärer Graphittiegel 776-247 ELTRA90190 ALPHA AR6247/AR053HD

Regulärer Graphittiegel 776-247 ELTRA90190 ALPHA AR6247/AR053HD

LECO 776-247 Regulärer Graphittiegel für typische Stickstoff-/Sauerstoffanalysen. Hersteller von Graphittiegel für LECO TC-400 TC-500 Ro-416, Eltra OH900 ON900, LECO /Eltra Analyzers Analyzer.

Graphittiegel Horiba 9052000200 für Horiba EMGA621W

Graphittiegel Horiba 9052000200 für Horiba EMGA621W

Horiba 9052000200 Graphittiegel. Hersteller von Graphittiegel für Horiba EMGA621W.

Graphit-Außentiegel Horiba 905.200.010.000/9052000100 Alpha AR1533

Graphit-Außentiegel Horiba 905.200.010.000/9052000100 Alpha AR1533

Horiba 9 05.200.010.000 Graphit-Außentiegel Alpha AR1533. Hersteller von Graphittiegel für Horiba EMGA-930.

das professionelle Team zu bedienen !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522