Keramiktiegel Leco 528-018. Hersteller von Kohlenstoff-Schwefel-Tiegeln und CS-Tiegeln für LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 AN. Wird für die Elementaranalyse des Kohlenstoff-Schwefel-Analysators verwendet.

Lesen Sie mehr...

Beidseitig offene Aluminiumoxidrohre werden häufig in verschiedenen Industrie- und Laboranwendungen eingesetzt . _ _ _ _ _ Sie sind ideal für den Einsatz in Prozessen wie Heizen , Kühlen und Trocknen und bieten eine hervorragende thermische und elektrische Isolierung . _ _

Lesen Sie mehr...

Aluminium - Keramiksubstratplatten sind die ideale Wahl für Anwendungen , die hohe Leistung , Zuverlässigkeit und Haltbarkeit erfordern . _ _ _ _ Es ist in verschiedenen Größen und Stärken erhältlich , um den unterschiedlichen Anwendungen gerecht zu werden .

Lesen Sie mehr...

Erreichen Sie mit unseren Bone Ash Cupels einen beispiellosen Reinheitsgrad. Diese Cupels wurden entwickelt, um Verunreinigungen und unerwünschte Elemente zu entfernen und ermöglichen es Ihnen, die wahre Essenz Ihrer Edelmetalle zu extrahieren.

Lesen Sie mehr...

Vorteile von Aluminiumoxidrohren: hohe Hitzebeständigkeit, gute Kältebeständigkeit, Hitzebeständigkeit, Beständigkeit gegen Säure- und Alkalikorrosion. Lange Lebensdauer. OEM wird akzeptiert.

Lesen Sie mehr...

Circle-Aluminiumoxid-Keramikstäbe haben ein höheres Verhältnis von Festigkeit zu Gewicht als andere Keramiken und können zur Herstellung leichterer und stärkerer Teile verwendet werden. Erhältlich in einer Vielzahl von Größen und Formen.

Lesen Sie mehr...

Ein Lumina-Tiegel und ein Boot werden häufig in der Labor- und Industrieanalyse sowie beim Schmelzen von Metall- und Nichtmetall-Materialproben eingesetzt. Erhältlich in verschiedenen Größen und Formen.

Lesen Sie mehr...

952018.906 100 μl Platin/Pt-Tiegel ( Probenschalen) für TA Instruments TA Q500/Q50/TGA 2950/2050 . Hersteller für TA-Tiegel und DSC-Probenschalen . Der TGA-Analysator von TA Instruments ist eine gute Alternative zu Probenbechern.

Lesen Sie mehr...

Zirkonoxidkeramik wird in Wellen, Kolben, Dichtungsstrukturen, der Automobilindustrie, Ölbohrgeräten, Isolierteilen in elektrischen Geräten, Keramikmessern, Ersatzteilen für keramische Haarschneidemaschinen mit hoher Dichte, Biegefestigkeit und Bruchfestigkeit verwendet. Wir können die Produkte gemäß den Zeichnungen, Mustern und Leistungsanforderun4

Lesen Sie mehr...

1. Stellen Sie Platin-/PT-Tiegel unterschiedlicher Größe herwie Sie brauchen.2. Senden Sie uns eine Konstruktionszeichnung oder Spezifikation von Platin/PT-Tiegeln. Hersteller von Platin-/PT-Tiegeln .CS CERMAIC CO.,LTD

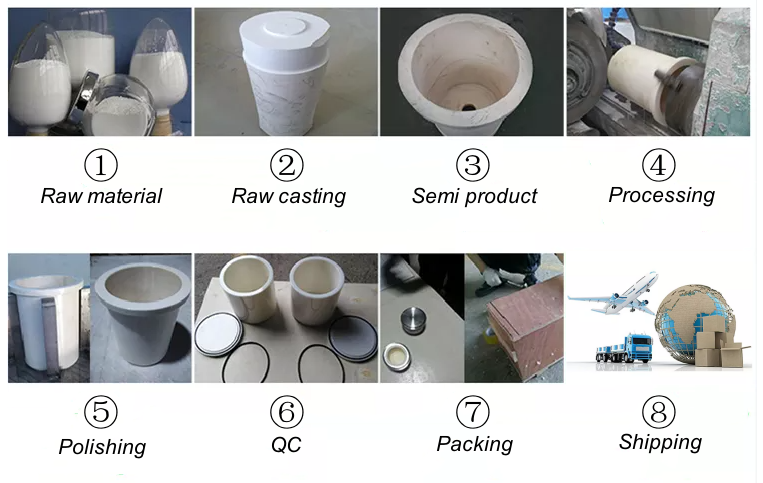

Lesen Sie mehr...Mahlbecher aus Aluminiumoxidkeramik mit Deckel sind in verschiedenen Größen, Formen und Farben für jede Anwendung erhältlich. Mit seinem luftdichten Verschluss eignet es sich ideal zum Mahlen und Mischen von Materialien in einer hygienischen, staubfreien Umgebung.

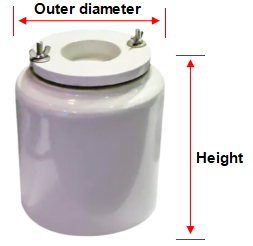

Art.-Nr. :

CS-A-13Farbe :

White90% 92% 95% 99.5% 99.7% 99%

Material : Alumina ceramic

1. Alumina ceramic milling jars with covers are extremely durable, making them ideal for grinding heavy and abrasive materials.

2. Heat resistant, ideal for high-temperature grinding operations.

3. Highly resistant to corrosion, which means they do not degrade over time.

4. Extremely low porosity, which means they are less likely to absorb contaminants during the grinding process.

5. Non sticky, which makes them easy to clean and maintain.

1. Alumina ceramic milling jar with cover is an essential tool for any serious laboratory or workshop.

2. It is made of high-grade alumina ceramic, which ensures long-lasting durability and performance.

3. Its generous capacity allows you to mill larger amounts of materials at once.

4. This jar is great for grinding, crushing, and mixing samples for a variety of applications.

| Item | Model & Specification | Capacity | Outer diameter * Height(mm) |

Appro.net weight

(in kgs)

|

| Alumina Ceramic Grinding Jars with Cover | CS | 30-40L | 400*600 | |

| XL size | 18-18.5 | 300*400 | 18 | |

| L size | 15-16 | 300*330 | 14~15 | |

| One-size | 10-14 | 270*320 | 11 | |

| Two-size | 5-6.5 | 220*260 | 9 | |

| Three-size | 3-5 | 180*250 | 6 | |

| Four-size | 1.5 | 150*180 | ||

| Five-size | 1 | 130*170 | 5 |

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry

| Item No. |

Outer Diameter

(mm)

|

Height

(mm)

|

Capacity

(L)

|

| CS-AM-012 | 300 | 350 | 10-15 |

| CS-AM-013 | 240 | 240 | 5L |

| CS-AM-014 | 190 | 190 | 2L |

1. Alumina ceramic milling jar with cover can be used for pulverizing minerals and other materials in a laboratory setting. The ceramic material provides an inert environment for grinding, allowing for precision and accuracy.

2. Ideal for use in food processing, pharmaceuticals and personal care products, where contamination must be controlled. This jar can be used to efficiently grind and mix ingredients without introducing any unwanted particles into the mix.

3. It is often used in the pharmaceutical industry for grinding active ingredients, excipients and other materials into a fine powder. The ceramic material ensures the purity of the product.

4. Widely used in high temperature furnaces. This jar is an ideal choice for accurately measuring and mixing materials in a high-temperature environment.

5. Ideal for use in industrial processes such as milling, grinding, and blending of powders and other materials. The ceramic material provides an inert environment that is resistant to abrasion and corrosion.

| Material | 85%Al203 | 90%Al203 | 95%Al203 | 99%Al203 |

| Al203 | 0.85 | 0.9 | 0.93 | 0.993 |

| Fe2O3 | ≤1.0 | ≤0.5 | ≤0.5 | ≤0.3 |

| Desnsity:g/cm3 | 3.4 | 3.5 | 3.6 | 3.85 |

| Vickers Hardness | ≥8.6 | ≥8.8 | 9 | 9 |

| Water Absorption:% | ≤0.2 | ≤0.1 | ≤0.085 | ≤0.01 |

| Refractoriness:℃ | 1580℃ | 1600℃ | 1650℃ | 1800℃ |

| Flexural Strength:Mpa | 180 | 200 | 240 | 280 |

| Wear Rate(at room temperatureerosion 100 grinding)% | ≤3 | ≤2.5 | ≤1 | ≤0.5 |

Q1. What information should we supply to get a quote?

Please offer the specification of alumina ceramic milling jar with cover, such as shape, dimension, quantity, application etc.

Q2: What types of materials can be milled in an alumina ceramic milling jar?

Alumina ceramic milling jars are suitable for grinding and milling a wide variety of materials, including chemicals, pigments, and other substances.

Q3: What size of alumina ceramic milling jar do I need?

The size of the alumina ceramic milling jar you need will depend on the size and type of milling media you are using

Q4: How often should I replace my alumina ceramic milling jar?

It depends on the frequency of use and the type of material being milled. Generally, alumina ceramic milling jars should be replaced after 1-2 years of use.

1. Wash the jar and lid separately with water to remove any debris.

2. Use a soft cloth and mild detergent to scrub the inside of the jar and lid.

3. Use a soft brush and mild detergent to scrub the outside of the jar and lid

4. Rinse the jar and lid with water, and then dry with a soft cloth.

5. Ensure that the grinding tank is dry when used again.

1. Visually inspect the jar for any signs of wear and tear such as cracks, chips, or any other visible damage.

2. Make sure the lid is properly sealed and there are no gaps that could allow for particles to escape.

3. Check the threads of the lid and the jar body for any signs of stripping or damage.

4. Ensure the lid fits tightly and securely on the jar body.

5. Inspect the seals around the lid and the jar body for any signs of damage or wear.

6. Check the interior of the jar for any signs of contamination such as dust, dirt, or other materials.

7. Überprüfen Sie das Äußere des Glases auf Anzeichen von Korrosion oder anderen Schäden.

1. Wir bieten personalisierte und maßgeschneiderte Dienstleistungen an, die auf Ihre persönlichen Bedürfnisse zugeschnitten sind.

2. Wir sind erfahrene Profis mit einer guten Erfolgsbilanz.

3. Wir bieten erstklassigen Kundenservice und reagieren umgehend auf alle Anfragen.

4. Wir bieten faire Preise und bemühen uns sicherzustellen, dass Ihre Gelder den besten Gegenwert erhalten.

5. Wir nutzen die neuesten Technologien und Werkzeuge, um sicherzustellen, dass Ihr Projekt nach den höchsten Standards abgeschlossen wird.

Aluminiumoxid-Keramik-Töpfe Mühle Mahlgläser

Aluminiumoxid-Keramik-Töpfe Mühle Mahlgläser

Aluminiumoxid-Mahlbecher hat eine hohe Reinheit, eine hohe Härte, Schlagfestigkeit, starke Säure- und Alkalibeständigkeit, Beständigkeit gegen verschiedene Lösungsmittel, Verschleiß.

Aluminiumoxid-Mahlkugel Verschleißfest 92 % 95 %

Aluminiumoxid-Mahlkugel Verschleißfest 92 % 95 %

Aluminiumoxid-Mahlkugeln sind hochdichte und ultrahochgebrannte Keramikkugeln, die in hochintensiven Rührwerksmühlen zum Fein- und Ultrafeinmahlen verwendet werden. Erhältlich in verschiedenen Größen.

99 % inerte Aluminiumoxid-Keramikkugeln – Katalysator-Trägermedium

99 % inerte Aluminiumoxid-Keramikkugeln – Katalysator-Trägermedium

Inerte Aluminiumoxid-Keramikkugel als Katalysator im Reaktor zur Abdeckung von Trägermaterial und Turmpackung. Erhältlich in verschiedenen Größen.

Aluminiumoxid-Keramik-Mahlglas / Kugelmühlenglas / Mühlentopf

Aluminiumoxid-Keramik-Mahlglas / Kugelmühlenglas / Mühlentopf

Aluminiumoxid-Keramik-Mahlbecher hat eine weite Öffnung und einen flachen Boden, was ein einfaches Rühren und effizientes Mahlen ermöglicht, erhältlich in einer Vielzahl von Größen.

Trockenmittelkatalysatorträger Aktivierte Aluminiumoxidkugeln 93 %

Trockenmittelkatalysatorträger Aktivierte Aluminiumoxidkugeln 93 %

Verschleißfeste Aluminiumoxid-Keramikkugeln, die häufig in der Präzisionsverarbeitung und Tiefenverarbeitung verschiedener Keramiken, Emails, Gläser und Hartstoffe in chemischen Fabriken als Mahlkörper für Feinzerkleinerungsmaschinen wie Kugelmühlen, Dosenmühlen und Vibrationsmühlen verwendet werden.

95% Aluminiumoxid-Keramik-Mühlgläser Kugelmahlglas

95% Aluminiumoxid-Keramik-Mühlgläser Kugelmahlglas

Kugelmühlen aus Aluminiumoxid-Keramik sind hochverschleißfeste Mahlbecher. Gleichzeitig bieten wir Ihnen auch einen gewöhnlichen Keramikkugel-Mahlbehälter und einen 99% Porzellan-Keramikkugel-Mahlbehälter.

0,5 l 1 l Aluminiumoxid-Keramik-Mühlgläser für Rollkugelmühle

0,5 l 1 l Aluminiumoxid-Keramik-Mühlgläser für Rollkugelmühle

Aluminiumoxid-Mühlenbecher sind hochverschleißfeste Mahlbecher. Gleichzeitig bieten wir Ihnen auch einen gewöhnlichen Keramikkugel-Mahlbehälter und einen 99% Porzellan-Keramikkugel-Mahlbehälter.

Kugelmühlenglas aus 99 % Aluminiumoxid-Keramik / Korundmühlengläser

Kugelmühlenglas aus 99 % Aluminiumoxid-Keramik / Korundmühlengläser

Das hergestellte Mahlglas hat eine monolithische Konstruktion, einen großen runden Bogenwinkel. Die Öffnung des Topfes kann leicht verschlossen und geöffnet werden, ein dichter Verschluss, eine schöne Form, hart und langlebig. Schlechte Phänomene wie Lücken, Lecks, Materialvorrat, Totraum usw. können dies nicht im Einsatz vorkommen.

das professionelle Team zu bedienen !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522