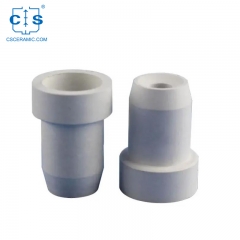

Keramiktiegel Leco 528-018. Hersteller von Kohlenstoff-Schwefel-Tiegeln und CS-Tiegeln für LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 AN. Wird für die Elementaranalyse des Kohlenstoff-Schwefel-Analysators verwendet.

Lesen Sie mehr...

Beidseitig offene Aluminiumoxidrohre werden häufig in verschiedenen Industrie- und Laboranwendungen eingesetzt . _ _ _ _ _ Sie sind ideal für den Einsatz in Prozessen wie Heizen , Kühlen und Trocknen und bieten eine hervorragende thermische und elektrische Isolierung . _ _

Lesen Sie mehr...

Aluminium - Keramiksubstratplatten sind die ideale Wahl für Anwendungen , die hohe Leistung , Zuverlässigkeit und Haltbarkeit erfordern . _ _ _ _ Es ist in verschiedenen Größen und Stärken erhältlich , um den unterschiedlichen Anwendungen gerecht zu werden .

Lesen Sie mehr...

Erreichen Sie mit unseren Bone Ash Cupels einen beispiellosen Reinheitsgrad. Diese Cupels wurden entwickelt, um Verunreinigungen und unerwünschte Elemente zu entfernen und ermöglichen es Ihnen, die wahre Essenz Ihrer Edelmetalle zu extrahieren.

Lesen Sie mehr...

Vorteile von Aluminiumoxidrohren: hohe Hitzebeständigkeit, gute Kältebeständigkeit, Hitzebeständigkeit, Beständigkeit gegen Säure- und Alkalikorrosion. Lange Lebensdauer. OEM wird akzeptiert.

Lesen Sie mehr...

Circle-Aluminiumoxid-Keramikstäbe haben ein höheres Verhältnis von Festigkeit zu Gewicht als andere Keramiken und können zur Herstellung leichterer und stärkerer Teile verwendet werden. Erhältlich in einer Vielzahl von Größen und Formen.

Lesen Sie mehr...

Ein Lumina-Tiegel und ein Boot werden häufig in der Labor- und Industrieanalyse sowie beim Schmelzen von Metall- und Nichtmetall-Materialproben eingesetzt. Erhältlich in verschiedenen Größen und Formen.

Lesen Sie mehr...

952018.906 100 μl Platin/Pt-Tiegel ( Probenschalen) für TA Instruments TA Q500/Q50/TGA 2950/2050 . Hersteller für TA-Tiegel und DSC-Probenschalen . Der TGA-Analysator von TA Instruments ist eine gute Alternative zu Probenbechern.

Lesen Sie mehr...

Zirkonoxidkeramik wird in Wellen, Kolben, Dichtungsstrukturen, der Automobilindustrie, Ölbohrgeräten, Isolierteilen in elektrischen Geräten, Keramikmessern, Ersatzteilen für keramische Haarschneidemaschinen mit hoher Dichte, Biegefestigkeit und Bruchfestigkeit verwendet. Wir können die Produkte gemäß den Zeichnungen, Mustern und Leistungsanforderun4

Lesen Sie mehr...

1. Stellen Sie Platin-/PT-Tiegel unterschiedlicher Größe herwie Sie brauchen.2. Senden Sie uns eine Konstruktionszeichnung oder Spezifikation von Platin/PT-Tiegeln. Hersteller von Platin-/PT-Tiegeln .CS CERMAIC CO.,LTD

Lesen Sie mehr...Art.-Nr. :

CS-DHP-G2001Farbe :

WhitePort :

Any ports of ChinaLieferdatum :

1-7 daysPurity : 99%

Shape : Tube

Material : Boron Nitride Ceramic

Boron Nitride Tube Features

1. Boron Nitride Ceramic Tubes has low thermal conductivity, good temperature resistance and thermal shock resistance.

2. Boron Nitride Ceramic Tubes has excellent electrical insulation properties, good dielectric properties, good radiation resistance and high frequency characteristics.

3. Boron Nitride Ceramic Tubes has excellent chemical stability, good corrosion resistance and high temperature oxidation resistance.

4. Boron Nitride Ceramic Tubes has high mechanical strength, good impact resistance, low friction coefficient and good wear resistance.

5. Boron Nitride Ceramic Tubes has good thermal shock resistance, high thermal conductivity and excellent temperature resistance.

6. Boron Nitride Ceramic Tubes has high temperature resistance, good corrosion resistance, high hardness and good wear resistance.

7. Boron Nitride Ceramic Tubes has good thermal shock resistance, good electrical insulation properties and excellent dielectric properties.

BN Tube Application

1.Boron nitride ceramic tubes have a wide range of applications.

2.They are non-conductive, thermally conductive, highly corrosion-resistant, and non-magnetic, making them suitable for use in a variety of industries.

3.The high temperature insulation properties of boron nitride ceramic tubes make them ideal for use in applications where

temperatures can reach up to 3180°F (1750°C).

4.Use in high temperature furnaces, kilns, and other high temperature processing equipment.

5.Boron nitride ceramic tubes can also be used as a barrier in chemical processing and other industrial applications.

6.Can protect components from corrosive agents and other hazardous materials.

7.Used in medical equipment, such as catheters, implants, and stents.

6.Non-toxic and biocompatible, making it safe for use in medical applications.

7.Used in electronics, such as circuit boards and semiconductor wafers.

8.Can be used to insulate electrical components and protect them from damage due to high temperatures.

BN Ceramic Propeties

| Grade | BN99 | CABN |

| Compositions | BN>98.5% | BN>97.5% |

| Binder | B2O3 | CaB2O3 |

| Density(g/cm3) | 1.95~2.0 | 2.0~2.1 |

| 25℃ Volume Resistivity(Ω·cm) | >1014 | >1013 |

| Max. Service Temp. (℃) | ||

| Oxygen | 900 | 900 |

| Inert Gas | 2400 | 2400 |

| High Vacuum | 2200 | 2200 |

| Three-point | 30 | 70 |

| Flexural Strength(Mpa) | ||

| Compressive Strength(Mpa) | 100 | 100 |

| Coefficient of Thermal Expansion | 1.5 | 2 |

| 25~1000℃(10-6/K) | ||

| Thermal Conductivity(W/mK) | 15 | 20 |

Ceramic Tube Specification

| Item | OD / mm | ID / mm | Length / mm | Purity |

| CS-DHP-G2001 | 8 | 4 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2002 | 12 | 8 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2003 | 20 | 16 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2004 | 28 | 22 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2005 | 35 | 25 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2006 | 46 | 40 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2007 | 62 | 54 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2008 | 80 | 74 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2009 | 70 | 60 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2010 | 80 | 70 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2011 | 15 | 7 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

| CS-DHP-G2012 | 20 | 12 | 100mmmm/200mm/500mm/1000mm/1200mm | 99% |

Boron Nitride Ceramics Test Standard

1.The test standard for boron nitride ceramic tubes is based on ASTM C1319, Standard Test Method for Thermal Conductivity of Refractories and Industrial Ceramics by Hot Wire Method.

2.This test method covers the determination of the thermal conductivity of monolithic refractory and industrial ceramic materials using the steady-state hot-wire or hot-rod method.

3.The test temperature range is from room temperature to 1000°C.

4.The thermal conductivity is determined by measuring the temperature gradient along a cylindrical specimen of known dimensions.

5.The specimen is placed in an electrically heated furnace with a thermocouple located near the center of the specimen.

6.The temperature gradient is measured by measuring the temperature at a specified distance from the center.

7.The thermal conductivity is calculated from the measured temperature gradient and the known dimensions of the specimen.

OEM Service

1.May vary depending on the particular application and intended use.

2.Should be taken into consideration when specifying an OEM boron nitride ceramic tube:

3.By taking these factors into consideration when specifying an OEM boron nitride ceramic tube, We ensure that your product meets your exact needs.

Packing & Shipping

We keep stock for almost all models of crucible in the warehouses .The shortest order lead time and delivery time can be within 5-7 days after receiving order confirmation, which ensures on time and in full delivery for any urgent order.

Warum uns wählen

Als professioneller Industriekeramiklieferant verfügen wir über eine Reihe von Vorteilen, die unseren Marktanteil im internationalen Handelsmarkt sichern.

1 . Zuverlässige Qualitätskontrolle, vollständige Spezifikationen, Unterstützung bei der Anpassung nicht standardmäßiger Produkte.

2. Professionelles und engagiertes Serviceteam.

3. Mehrfacher Schutz der Verpackung, sicher und zuverlässig.

4. Hocheffizienter Lieferkanal, sicher und zuverlässig .

FAQ

1.F : Was sind Bor- on - Nit - Ride - Keramikröhren ?

A : Bor - auf - Nit - Ride - Keramikröhren sind Röhren aus einem äußerst hitzebeständigen Keramikmaterial . _ _ Sie sind temperaturbeständig bis 3.000 ° F und halten hohen Drücken stand . _ _ _ _ _ Sie werden in Anwendungen eingesetzt , bei denen Thermoschockbeständigkeit erforderlich istund elektrische Isolierung sind erforderlich .

2.F : Welche Vorteile bietet die Verwendung von Bor- on - Nit - Ride - Keramikröhren ?

A : Bor - on - Nit - Ride - Keramikrohre bieten eine hervorragende Temperaturwechselbeständigkeit und elektrische Isolierung und sind daher ideal für Hochtemperatur- und Hochdruckanwendungen . _ _ _ Außerdem sind sie leicht und einfach herzustellen . _

3.F : Welche verschiedenen Größen und Formen gibt es für Bor - on - Nit - Ride - Keramikrohre ?

A : Bor- on - Nit - Ride - Keramikrohre sind in verschiedenen Größen und Formen erhältlich , von kleinen Rohren bis hin zu großen Zylindern . Es können auch individuelle Größen und Formen hergestellt werden .

Vorherige:

Bornitrid-KeramikdüseNächste :

Zylinder-Bornitrid-Tiegel mit Deckel Bornitrid-Keramikteile

Bornitrid-Keramikteile

B- oder On - Nitrid - Keramiken sind ein heißes neues Material auf dem Markt für Hochleistungskeramik und werden in einer Vielzahl industrieller Anwendungen eingesetzt . _ _ _ _ _ _ B N ist ideal für Anwendungen , die eine hohe Wärmeleitfähigkeit , chemische Inertheit und _ und elektrische Isolierung .

Bornitrid-Keramikplatte Heißgepresste sechseckige quadratische BN-Platte

Bornitrid-Keramikplatte Heißgepresste sechseckige quadratische BN-Platte

Bornitridplatte / -blatt wird aus pulverisiertem hexagonalem Bornitrid durch Hochtemperatur-Vakuum-Heißpresssintern hergestellt. SAM beliefert Kunden mit hochwertigen Bornitridplatten / -blechen.

Bornitridstäbe / Bornitridkeramik

Bornitridstäbe / Bornitridkeramik

Bornitrid ist ein ausgezeichneter elektrischer Isolator, der eine höhere Oxidationstemperatur hat. Es bietet eine hohe Wärmeleitfähigkeit und eine gute Temperaturwechselbeständigkeit und kann mit engen Toleranzen in praktisch jeder Form bearbeitet werden.

Zylinder-Bornitrid-Tiegel mit Deckel

Zylinder-Bornitrid-Tiegel mit Deckel

Bornitrid ist ein synthetischer technischer Keramikwerkstoff. Es verfügt über hervorragende thermische Eigenschaften. und ausgezeichnete Thermoschockbeständigkeit. Die einzigartige Eigenschaft des BN-Tiegels besteht darin, dass er nicht mit geschmolzenem Metall benetzt wird.

Bornitrid-Keramikdüse

Bornitrid-Keramikdüse

Bornitrid (BN)-Düsen aus heißgepresster Bornitrid-Keramik weisen eine hervorragende Temperaturschockbeständigkeit auf. Risse oder Brüche treten nicht auf, wenn Bornitrid-Düsen plötzlichem Erhitzen oder Abkühlen ausgesetzt werden.

Aluminiumoxiddeckel für 3,4-ml-Tiegel GB445213 für Netzsch

Aluminiumoxiddeckel für 3,4-ml-Tiegel GB445213 für Netzsch

Tiegeldeckel aus Aluminiumoxid für Netzsch . Hersteller für Tiegel und Probenbecher von Netzsch. Netzsch Instruments gute Alternative zu DSC-Probenschalen.

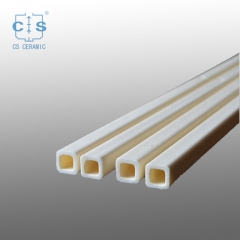

Quadratische Aluminiumoxid-Keramikrohre, ein Loch, 1–2000 mm

Quadratische Aluminiumoxid-Keramikrohre, ein Loch, 1–2000 mm

Quadratische Aluminiumoxidrohre haben eine hohe Korrosionsbeständigkeit, eine ausgezeichnete Temperaturwechselbeständigkeit und eine hohe Wärmeisolierung . Eine Vielzahl von Spezifikationen verfügbar. OEM/ODM ist akzeptabel.

Zirkonoxid-Keramik-Zylinderhülse ZrO2-Auskleidung für Schlamm- und Hydraulikpumpen

Zirkonoxid-Keramik-Zylinderhülse ZrO2-Auskleidung für Schlamm- und Hydraulikpumpen

Die Zirkonoxid-Keramik-Zylinderhülse ist eine wichtige Komponente in Kolben-, Plungerpumpen und Hydraulikzylindern, die ständiger Hin- und Herbewegung und hohen Belastungen standhalten.

das professionelle Team zu bedienen !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522